Looking For 3D Scan And Reverse Engineering Services?

If you have ever needed to make a copy of an existing object, tool, or device, you have probably looked into 3D scan and reverse engineering services. But 3D scan and reverse engineering services might be hard to find in your area if you do not know where to look.

If you are looking for 3D scan and reverse engineering services, it is crucial to find a professional company. Searching online, asking your colleagues and/or clients for references, and asking your business acquaintances can all help you find the ideal partner.

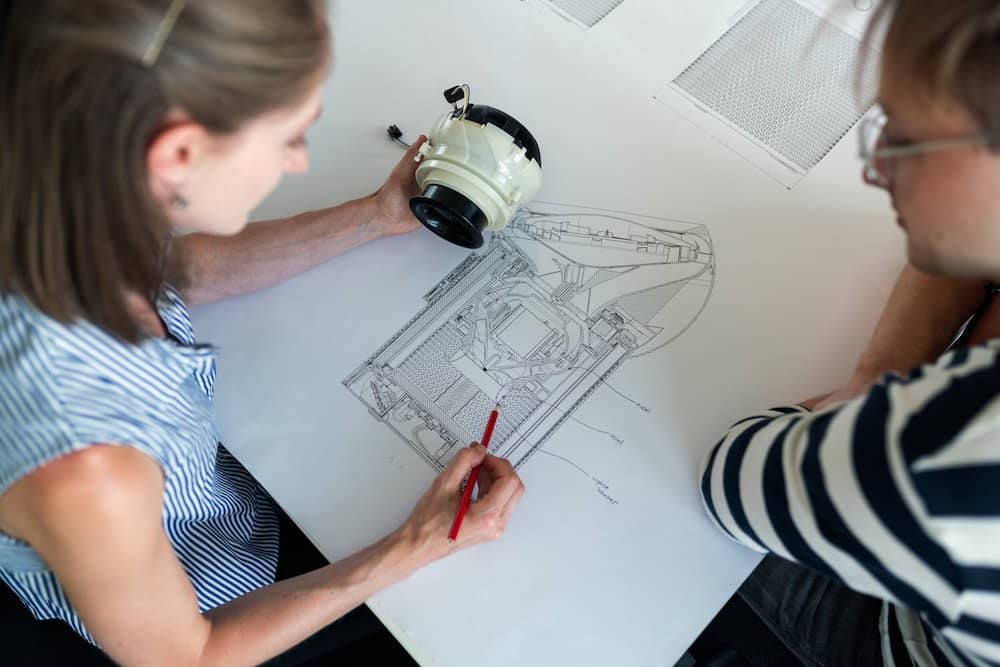

One way 3D scan and reverse engineering services are useful is in recreating objects and products without the original design plans. Performing a 3D scan of an object is one of the first steps in reverse engineering, and the two processes are often paired. Understanding the benefits and why you would need these services could help you.

What companies offer 3D scan and reverse engineering services?

Since 3D scan and reverse engineering services are almost always paired together, most companies provide both services together. 3D scanning is often packaged into the reverse engineering process and is viewed as one large service.

There are many options available if you are looking for 3D scan and reverse engineering services. You will find many companies that provide these services in the whole country. Some are even large enough to have an international presence as well.

That being said, there are also more local options, so you should always look around to see what suits your needs best.

Selecting a 3D scan and reverse engineering company

Selecting a company to provide you with 3D scan and reverse engineering services can be a difficult task. How do you make sure you are choosing the best business to work with at the best cost and value?

For your project, you should aim to get at least 3 quotes and then weigh your decision on the following criteria. Depending on your objectives, you could even rank these to help your decision process.

- Total cost, lead time, responsiveness, and support

- Geographic location/proximity to you

- 3D scan technique

- Past client reviews and referrals

- Additional services offered

All facets of each 3D and reverse engineering service provider need to be considered when deciding on who to partner with.

What types of industries use 3d scan and engineering services?

Many types of industries and businesses use 3D scan and engineering services. All of them that use these services do so for the same reasons: they need something recreated and reengineered. Some industries use 3D scan and engineering services more often than others.

- Automotive manufacturers

- Aerospace manufacturers

- Consumer product manufacturers

- Industrial equipment manufacturers

- Medical equipment manufacturers/health providers for creating prosthetics

Various industries and companies use 3D scan and reverse engineering services to re-create different objects. The amount of businesses that use 3D scan services is almost endless.

What is the purpose of a 3d scan service?

3D scanning uses a laser or another method to record the 3-dimensional shape of an object. 3D scanners are usually enclosed areas of various sizes that have lasers, cameras, or other sensors pointing toward the center of the chamber from all directions to measure the 3D shape of the object.

It is important for the laser to view the object from each angle to ensure they record a great representation of the object. 3D scanning of existing objects can be done for many reasons.

- Replicating existing objects

- Creating a CAD representation of an object to have a digital backup, also known as digital twin

- Quality control- the 3D scan can be compared to CAD design data

- Reverse engineering of the part

If an important mold for a rubber piece in a manufacturing line is broken, a rubber piece that was made by the mold can be 3D scanned. From that information, the mold can be recreated in a program like CAD after being 3D scanned. Without 3D scanning, the mold would not be recreated as easily, and production could be shut down for too long!

3D scan services go hand-in-hand with reverse engineering. If you would like to determine how an existing object is manufactured, 3D scanning is usually the first step in the much longer process of reverse engineering. Engineers can work backward to determine the shape of the mold, tooling, and other manufacturing components.

3d scanning methods

3D scanning has been around for decades. Over time the 3D scanning technology has become much more sophisticated. The two main types of 3D scanning are contact scanning and non-contact scanning.

While the two different types of 3D scanning might sound self-explanatory, they have their own properties that you should be aware of.

Contact 3d scanning

You are probably able to guess that the use of contact scanning means the object you are having scanned comes into contact with the scanning components. Contact scanners physically touch the object being scanned, with the object either being placed on a flat surface on the scanner or held in place by a fixture.

Since a contact scanner has to touch the object, it is not ideal for delicate objects since it can alter or damage the object. Contact scanners can have two different mechanisms to scan the objects.

- Articulating Robotic Arm: As the arm moves across the surface of the objects, sensors on the joints perform complex calculations to determine the shape of the object.

- Carriage System: The sensor moves horizontally across a track. Carriage systems only work well for relatively flat objects with minimal curvature.

Since contact 3D scanners have moving parts, they tend to wear down, break and require more maintenance than non-contact 3D scanners. Contact 3D scanning is becoming less and less common as the technology behind non-contact 3D scanning becomes more advanced.

Non-contact 3d scanning

Non-contact scanning is the more advanced method. X-ray, light, lasers, or ultrasound technologies are used in some 3D scanners. Besides being more advanced, non-contact 3D scanning has the benefit of never having to touch the object, making it a great method for delicate objects like artifacts or brittle/damaged components.

There are a few types of non-contact 3D scanners that are available, and each one has different benefits that are used in various applications. Here are some examples of the most common types:

- Time-of-Flight 3D Scanners

- Triangulation 3D Scanners

- Conoscopic Holography 3D Scanners

- Modulated Light 3D Scanners

- Structured Light 3D Scanners

- Photogrammetry 3D Scanning

There are other types of non-contact 3D scanners, but these are far less common since technological advances have improved the other methods.

- Silhouette 3D Scanners

- Stereoscopic 3D Scanners

- Photometric 3D Scanners

3d scanning benefits

Typically, a 3D scan is not harmful to the object being scanned, especially with non-contact scanners. Since it is not a destructive process, the object you are having a 3D scanned will still be around and functioning.

Non-contact 3D scanners have lasers or other methods that scan the object, and nothing touches it besides light, x-rays, or ultrasonic signals! 3D scanning is beneficial for recreating parts and objects:

- It ensures parts will fit properly right away without having to test then check and reiterate

- 3D scanning is a swift, simple process

- Correction and improvements can be made easily after 3D scanning

- Saves design cost- 3D scanning is less costly than designing from the ground up

- Manufactured parts can be easily compared to the design for quality control purposes

It also provides the client with a CAD model, useful if the object was created before CAD software or if the CAD files were lost or destroyed! Whatever the main benefits are to you, you will probably find that 3D scanning is a service that you can easily find and arrange to have completed on your parts/objects.

Digitize with 3d scan services

3D scanning an existing object allows the owner of the object to digitize it into a CAD file and store a backup on their computer and/or the cloud. Oftentimes, objects are 3D scanned because a replacement is not available, the plans were destroyed, or proper records were not maintained.

3D scanning is a great way for manufacturers to create backup plans for their existing manufacturing components. Almost any object in the manufacturing process can be 3D scanned. The possibilities are endless.

- Tooling dies, and molds

- Full products and component parts

- Vehicles, planes, and other transportation vehicles

- Cell phones and consumer electronics

- Buildings, bridges, and other infrastructure

3D scanners can even scan people! Many filmmakers use 3D scanner techniques to film actors for roles that will be digitally edited later.

Design a new part or redesign

3D scanning is usually a stepping stone in creating or redesigning a part or product. Once you have the 3D data scanned and loaded into CAD software, an engineer can perform a redesign and/or work backward with the 3D information to determine how it is made.

Being able to do this makes it far easier for someone to make changes, even allowing those changes to be seen and tested quickly.

Update models for easier tooling of parts

Once the existing object has been 3D scanned, tooling (the equipment used to manufacture the object) can be recreated. By knowing the dimensions of the object, a mold, stamp, or other tooling can be created to recreate a physical version of the original object!

This makes working backward even easier, providing all the tools needed to understand an object.

Create an efficient manufacturing process

The added benefit of having to recreate the tooling is that it can be redesigned in a better way. Sometimes better and more efficient tooling can be created that will save manufacturing time and provide better yield, which will ultimately save the manufacturer money.

A good manufacturer will routinely evaluate their manufacturing lines and look for cost savings. Having a part that they are manufacturing 3D scanned and looked at from a reverse engineering standpoint can uncover faster, better, and less costly manufacturing methods!

Reverse engineering

Reverse engineering is typically the end goal when having an object 3D scanned. Reverse engineering is done for a few reasons, mainly to recreate the object that was scanned or to make a different and better version of the object.

Reverse engineering has been around since people started inventing objects. It is a great method to:

- Determine how something works

- Improve the design

- Create a better competitive product

- Analyze your own design for improvements/modifications

Besides having an object or product 3D scanned, more steps have to be taken to reverse engineer something successfully. The function of the object and the inside components must be known too.

Disassemble the object

To fully understand how an object works, it has to be taken apart. All of the internal components have to be noted, and a detailed assessment of how each component piece works together will need to be created.

There may be internal components that will also require a 3D scan. This will add time and cost to the process of 3D scanning and reverse engineering.

Internal and exterior components will also need to have the material makeup determined. If it is plastic, what type of plastic is it? If it is a metal, what is the type of metal? There are advanced testing machines and methods used to determine material composition.

After tearing apart the object or product, the next step is to determine how to recreate it and possibly even make it better!

Determine how the object works

Determining how an object or product functions is probably the most difficult and time-consuming part of the process of reverse engineering.

Not only do the dimensions and components have to be understood, but the reverse engineering service provider must also determine how the components parts function together and how they can change it or make it better.

Create a product that performs the same function

If you are a manufacturer that would like to create an object or product that is similar to an existing version, reverse engineering is the service and method you would use to get this done. However, change is an important part of the process for various reasons:

- Change is necessary to ensure that copyrights and patents of the original object are not being violated.

- Change provides a great opportunity for the reverse engineering service to create a better but different design.

- Change allows the creation of a design that is easier to manufacture.

Creating a better product that is easier to manufacture will let you stomp out the competitors and provide you with higher revenue and profit.

What are the purposes of 3d scan and reverse engineering services?

The purpose of 3D scan and reverse engineering services are to recreate objects or products. However, the reasons for recreating objects vary depending on the situation and an individual’s needs.

For instance, CAD files/plans or tooling for making the object could have been lost or destroyed, requiring a replacement or to create a competitive version.

What are the benefits of 3d scanning and reverse engineering?

The main benefit of 3D scanning and reverse engineering is that you do not have to start from scratch to redesign or recreate an object! Why recreate the wheel? You can take the information that is available and reapply it to remake the design. Sounds much easier, right?

In the long run, 3D scanning and reverse engineering services save time and money when compared to designing and creating something from the ground up.

How long does 3d scanning and reverse engineering take?

The length of time 3D scanning takes depends on the size of the object. The typical time for a 3D scan is anywhere from 10 minutes to multiple hours or days.

Reverse engineering can be a much longer process, taking days or even weeks to months to accomplish. The time it takes to reverse engineer something varies so widely because it depends greatly on the complexity of the object.

If the object is a simple molded part, you can expect that it could be reverse-engineered within days or sooner.

If it is a complex part with moving and/or electrical components, the reverse engineering process will be on the high end of the estimate, weeks to months. The process of reverse engineering complex parts has to go through multiple iterations and tests before an approved, high quality, and viable solution is determined.

How much does 3d scanning and reverse engineering cost?

The cost of 3D scanning depends on the method of 3D scanning used. It also depends on the size of the object and how complex of a shape it is. 3D scanning can cost:

- Over $1,000 for complex and large objects

- As low as $100 for small, simple objects

Reverse engineering services cost more than 3D scanning, typically over $1,000. Pricing is higher depending on the complexity of the object, though it could be lower for simple objects.

Conclusion

If you are looking for 3D scan and reverse engineering services, you should now have a great place to start and know where to look. Remember to consider cost, lead time, responsiveness, and geographic location when selecting a company to provide you with 3D scan and reverse engineering services.

Contact us

Whether you just have a small question or want to get a customized offer from us:

Contact us now.

We are happy to help you.