Green Prototype

Making prototypes more sustainable

Motivation

The production, use and disposal of conventional prototypes have a massive negative impact on the environment.

Most prototypes are designed for short-term use only. Due to time pressure and the reduction of construction costs, simple manufacturing methods (e.g. gluing) are applied for manufacturing, which don’t allow dismantling of separate parts. This hinders proper recycling or the reuse of basic versatile modules.

As fiber composites are often used, most prototypes can only be disposed as hazardous waste and thus the resource is wasted.

Aim of the project

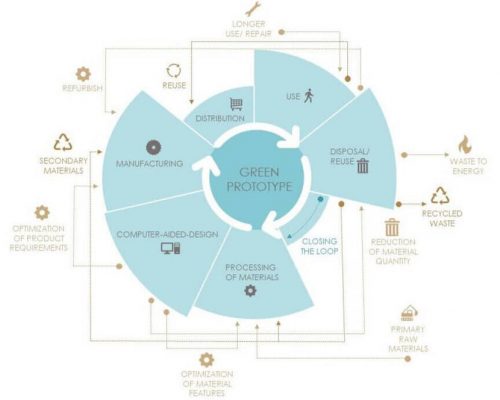

New design technology, computer-aided design (CAD) and innovative and holistically-thinking manufacturing processes, as well as the use of eco-friendly materials provide an alternative to traditional prototype production.

This approach is based on modular product manufacturing, the introduction of a circular economy in the product’s lifecycle and therefore expanding the materials cycle through optimized recycling and reuse systems.

Changing the industry’s production traditions can be challenging, therefore this approach presents ideas on how to create change within different areas of the product’s lifecycle.

Vision

A sustainably-produced prototype drastically reduces the environmental impact compared to traditional models.

By including future-thinking and more sustainable design and production methods within your company’s existing routines, you can not only be a pioneer in the engineering sector, but also play an active part in changing mindsets within your industry.

We are constantly informing ourselves about new manufacturing techniques and sustainable engineering approaches and critically question existing strategies.

We are in active exchange with our partners and networks in order to discuss arising ideas and thoughts. This is how we ensure transparency, quality and focus on the main objectives.

sustainably-produced prototypes drastically reduce the environmental impact.

ECO-friendly materials

In order to choose suitable materials, we use criteria such as: ecological cultivation, EU origin, natural resources, durability and recyclability. The materials we choose have been carefully examined. However as there is no perfect material, we communicate our choices transparently.

Product life cycle

Consumer goods undergo a life cycle from production to use and through to disposal. Using the life cycle assessments tool, each section of a product’s life cycle can be analyzed by different factors such as energy efficiency, durability and environmental impacts. This constitutes an overall analysis of the product’s properties.

Circular life cycle

Traditionally, product life cycles are seen as linear: beginning with the production and ending with a disposal of the item. New approaches describe a regenerative system: a circular life cycle. This ascribes all product parts into constant use cycles with the aim of generating as little residual waste as possible. This model emphasizes the importance of efficient recycling and reuse of resources.

Contact us

Whether you just have a small question or want to get a customized offer from us:

Contact us now.

We are happy to help you.