Projects

The Refit Night Express

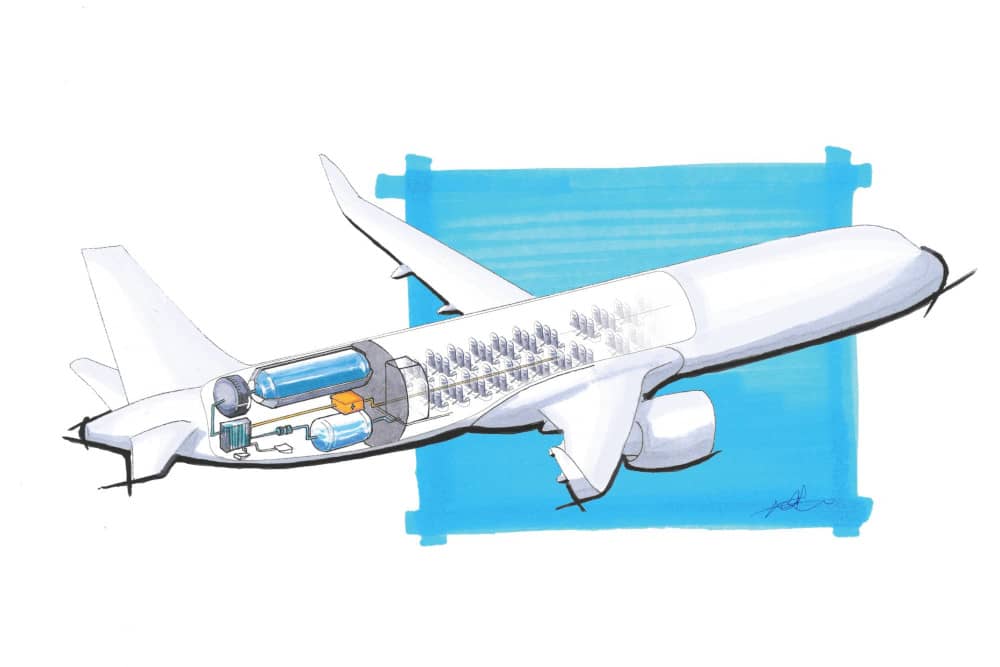

Hydrogen Aviation Systems

DLR Mock up

Smart Kitchen

This full-size prototype presents an authentic copy of the original and includes functional ‘Plug & Play’ interfaces for electrical equipment such as ovens, microwaves and freezers.

Green Prototype

This approach demonstrates a holistic and full-on sustainable concept of how to revolutionize engineering, design and manufacturing of conventionally built prototypes in the existing industry.

DIGITIZATION OF PIPELINES

The project – currently under development – focuses on the automated recording of installed pipes in ship engine rooms. Due to the innovative method of digitization of pipe geometry, this approach revolutionizes the sector by offering a digital twin of ship engine rooms.

Automatic Camera Crane

This multifunctional camera crane is fully automatic, remote controllable via tablet and can be mounted on any vehicle. This project displays how the requirement for user-friendliness can be combined with a highly technical product specification.

ALTIMETRY CRUISE “AIDA”

A complete set of altitude measurements were taken of the cruise ship AIDA. The use of 3D scanners ensured outstanding accuracy and detailed results within a matter of days.

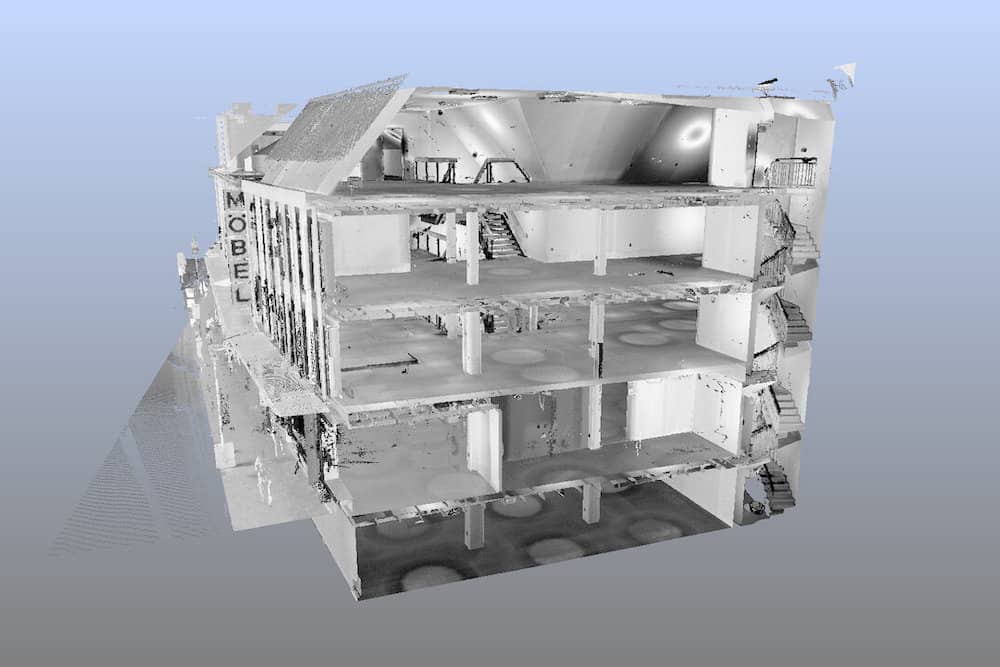

Real estate scanning

The scan of a complete furniture store enables a 3D visualization of building characteristics as well as the reconstruction and development of floor plans and facades.

Renovation of an old farmhouse

A 150-year-old farmhouse underwent a complete renovation of the interior and exterior. Because no drawings were available and the house was rebuilt several times, a 3D survey was taken. The complete plot was also recorded for possible further constructions.

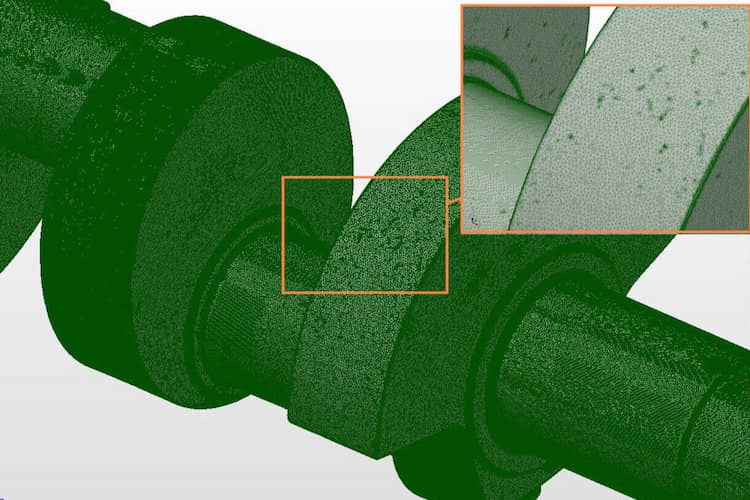

Digitization of a compressor

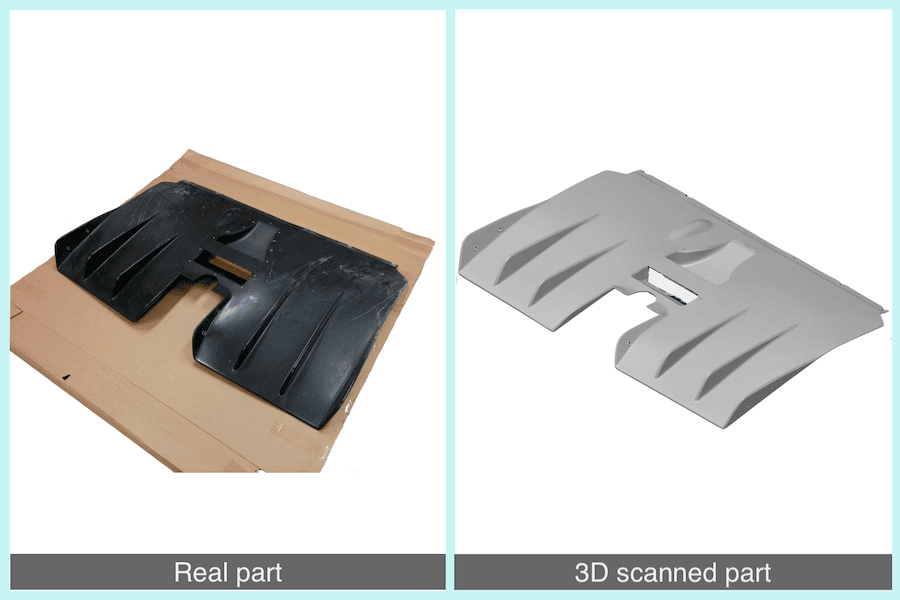

Bracket with Dimensional Deviations

This bracket was constantly manufactured with discrepancies to its dimensional specifications. By scanning the bracket multiple times we identified a deviation trend. A modification of the design was proposed, resulting in an accurate, stable, and repeatable product.

Verification of Pipe Flange Positioning

For a pipe exchange, the flange hole positioning and flange orientation are particularly important. In order to verify that the pipe corresponds to the 3D data, a false color analysis was conducted.

GAS COMPRESSOR REVERSE ENGINEERING

This gas compressor had no drawings available. A replacement appeared at first to be difficult. However, by scanning the compressor and transferring the data to specialized software, we can now produce this item multiple times and ensure that the quality of the copies.

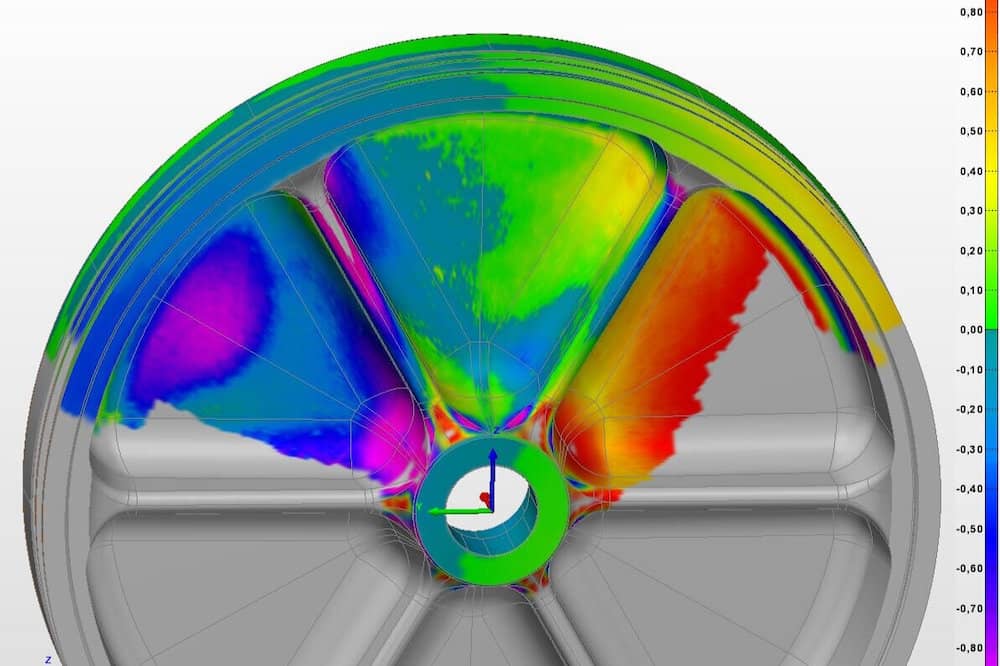

PARAMETRIC REVERSE ENGINEERING FOR AERODYNAMICS

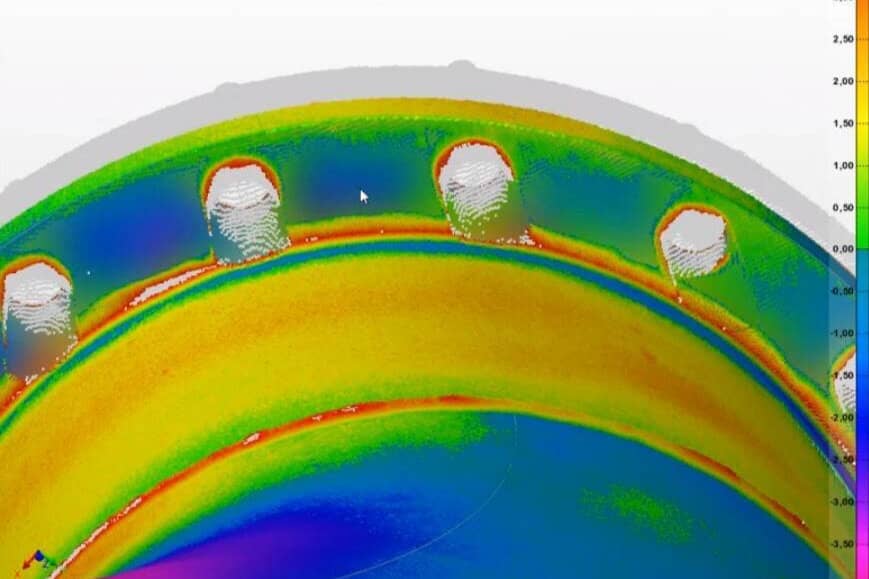

3D MODEL OF A BALLAST WATER TANK FOR THE CORRECTION OF TRIM TABLES

Ballast water tanks on ships make an essential contribution to floating stability. We were called to help on calculating the filling level and ballast weight.

With our 3D-scanning equipment, we measured the tank from the inside, which extended over 3 floors. Based on this we were able to create a 3D volume model of the tank and simulate different filling levels.

The big advantage of this measurement and simulation is that the tank does not have to be physically aligned for different trim angles or inclination angles.

Contact us

Whether you just have a small question or want to get a customized offer from us:

Contact us now.

We are happy to help you.