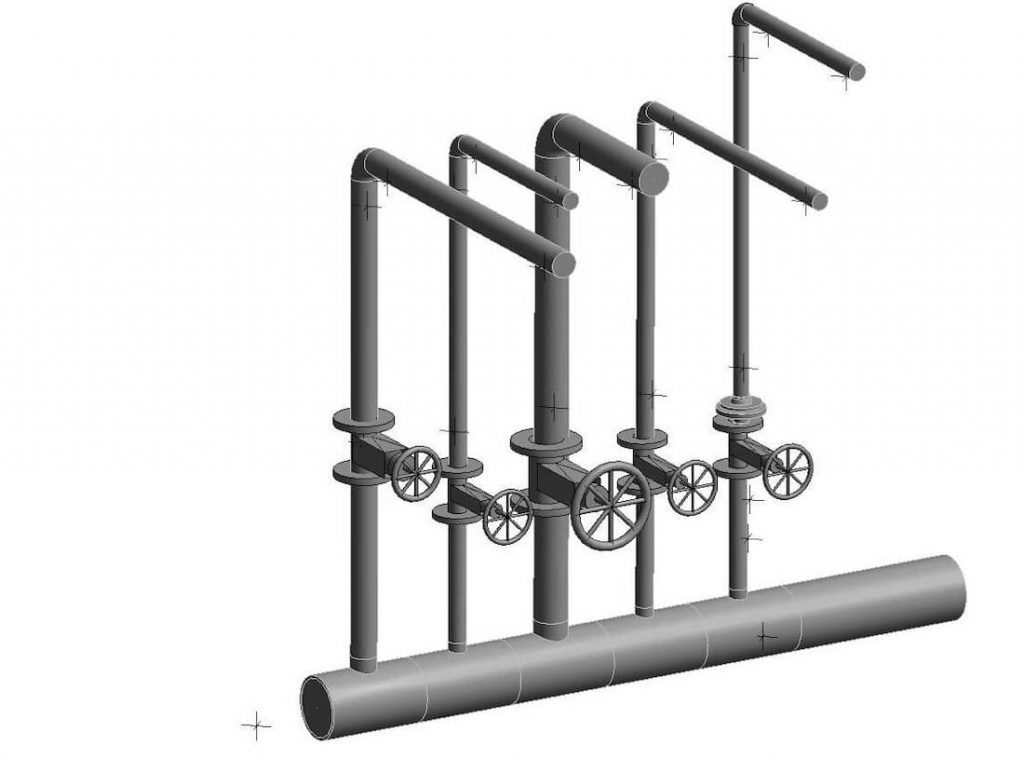

Digitization of pipelines

3d scan of pipes on ships for spare parts production

Funding Project

During the course of their life cycle, the pipes of ships need to be repaired and replaced frequently. The production of spare parts is associated with major challenges. Plans and documentation are incomplete or not up to date, so the pipes to be replaced have to be remeasured.

The measurement of the pipe geometry is very time-consuming; it is necessary to dismantle the pipes to be replaced as well as the surrounding pipes. The affected plants must be shut down and, under certain circumstances, the laytime of the ship will be prolonged. In addition, manual measurement is error-prone, and the subsequent creation of design data and manufacturing drawings involves a great deal of time and effort.

Project Duration

01/06/2020 - 31/01/2023

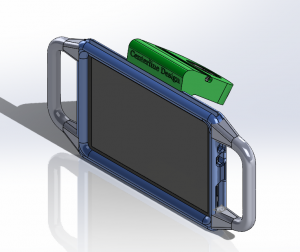

The development project Pipe digitization in operation pursues the goal of advancing the digitization of machine rooms and plants. A mobile and flexible surveying instrument was developed as part of the project. The instrument can be used to digitize the geometry of pipelines in their installed state.

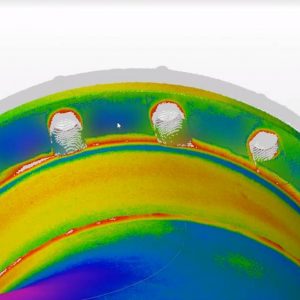

In addition, the recorded data can be supplemented with further measurement data, such as material thickness, and these can be stored in the digital model. With the help of the measurement process, it is possible to digitize existing plants without having to shut them down, which means enormous time and cost savings for the operator.

By digitising machine rooms, repair work can be carried out faster and more precisely than with conventional methods. The obtained data are made available to the customer and can be used for further work, such as modernisation measures (retrofit). This innovative approach opens new possibilities for ship maintenance.

contact us

Whether you just have a small question or want to get a customized offer from us:

Contact us now.

We are happy to help you.