Quality assurance

Scan. Compare. Report.

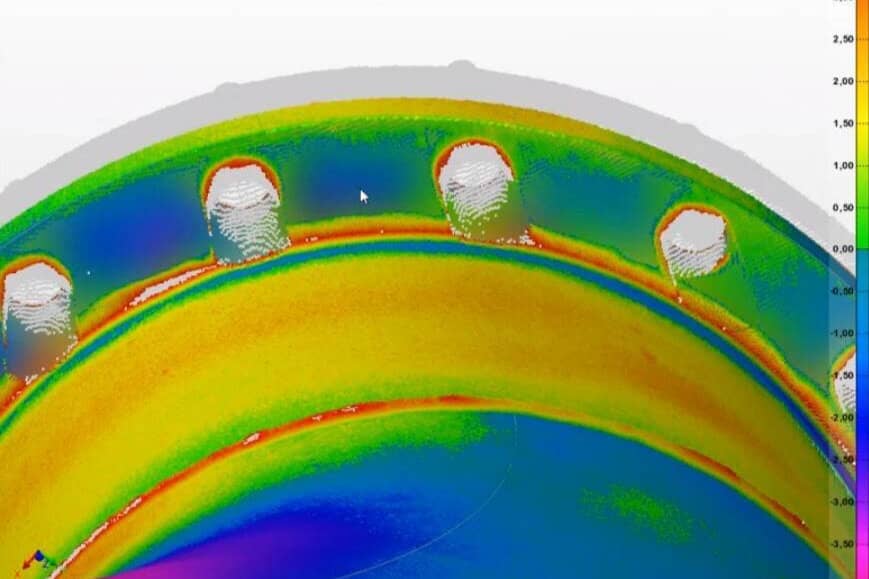

Visual colored reports to identify discrepancies in any product.

How it works

1. scan the component

We are equipped with a number of highly accurate 3D measurement tools and technology, which enables the scan of any component.

2. Compare to CAD Data

By making use of different pieces of specialized software, we post-process the data in order to create a 3D model. We then compare this 3D model with the original CAD data.

3. Create colored report

We create a multi-colored report with visualizations of the discrepancies.

Image Accordion #1

Image Accordion #2

Image Accordion #3

Verification of Pipe Flange Positioning

For a pipe exchange, the flange hole positioning and flange orientation are particularly important. In order to verify that the pipe corresponds to the 3D data, a false color analysis was conducted.

Bracket Manufactured with Dimensional Deviations

This bracket was constantly manufactured with discrepancies to its dimensional specifications. By scanning the bracket multiple times we identified a deviation trend. A modification of the design was proposed, resulting in an accurate, stable, and repeatable product.

contact us

Whether you just have a small question or want to get a customized offer from us:

Contact us now.

We are happy to help you.