What Is 3D Laser Scanning In Construction

While construction is slow to adopt new technology, the industry has adopted a few new devices, techniques, and designs to make projects more cost-effective. One such technology, 3D laser scanning, has the potential to help companies complete tasks quicker and more reliably.

3D laser scanning uses lasers and light-sensitive equipment to measure distances around objects and locations. Processing these measurements creates digital 3D models you can use to speed up projects and create more cost-effective builds.

You can make the technology as straightforward or as complex as you need and want. Either way, following a set of 3D laser scanning best practices is the key to successfully using the technology. You will find the more common best practices below, along with popular construction applications.

Why 3D scanning is used in construction

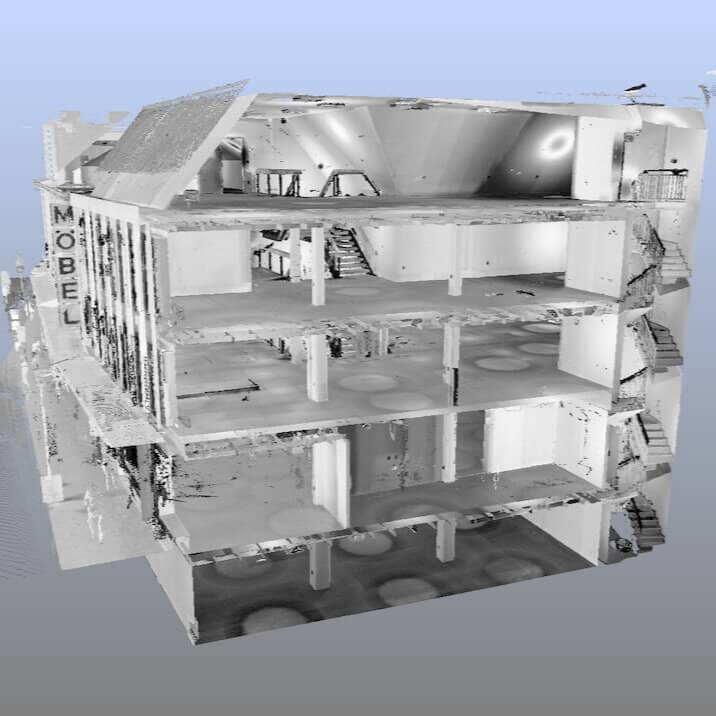

At its heart, 3D laser scanning, high-definition surveying (HDS), or reality capture, is a non-destructive, non-contact measuring technique for producing digital models. You can use it to scan a physical object or its installation location. Either way, you will end up with a model containing the target’s exact shape and size.

The technology can produce both 2D and 3D models, though 3D is typically the more useful option. These 3D computerized representations, called point clouds, can capture free-form shapes in extremely fine and accurate detail.

Overall, 3D laser scanning works best when you must accurately inspect and measure complex geometries. The technology lets you get into places where traditional measuring technologies fail or cannot reach.

The 3D laser scanning process

As with any tool, you can make 3D laser scanning as complicated or as simple as you need it. Laser scanners can capture three-dimensional data efficiently, accurately, and precisely. You can configure them to work with any size, shape, or surface features.

To gather data, you need to place your scanner in different positions in order to capture the complete space from all possible angles. For each position, specialized software directs the laser around while a pair of optical sensors measure the reflected light’s distance and orientation.

The resulting data

Converting point clouds to models

While you can use the point cloud as-is, you will most of the time want to convert it into an actual model. You can do this through any 3D modeling solution that supports your cloud data files. Where you go from there largely depends on your specific application.

Data inspection

CAD model reverse engineering

Common construction 3D laser scanner applications

Despite the initial slow adoption, 3D laser scanning is being increasingly used in the construction industry, including both repairs and new builds.

Some of the more popular applications include:

- Virtual design and construction

- Collecting geospatial data of a job site

- Verifying architectural documentation and facility coordination

- Offsite measurements at any point of time

- Quality assurance

- Deformation analysis and overhead clearance verification

- Coordinating historical preservation

- Developing, sequencing, and scheduling 3D models for prefabrication

Validating proper design execution

You can use your laser scanner for quality assurance evaluations without delaying in-progress projects. You can also compare actual site conditions to as-designed drawings and models to identify potential problems before your contractors start building.

Measuring and evaluating progress

Because you can complete the scans quickly, laser scanning lets you assess project progress. You can rescan the build multiple times through a project’s lifecycle. It can ensure that you and your clients know if things are going as planned or if something is amiss.

3D building models

Prefabrication process and utilities

As many construction projects move to prefabricated components, construction firms find themselves maintaining factories and manufacturing facilities. 3D laser scanning can reveal any potential conflicts on your prefab lines. It can also show you potentially hazardous working conditions.

Facility and building renovation

3D laser scanning can fill in the gaps found in inaccurate or incomplete as-built documents and drawings. You can produce excellent models of both the interior and exterior aspects of existing facilities. These models will then reduce errors and problems in your design plan.

The benefits of using 3D laser scanning in construction

3D laser scanning provides numerous benefits for any industry, but construction companies can reap many rewards just by implementing the technology. It may cost more than traditional surveying techniques, but laser scanning often pays for itself within one or two projects.

Improved planning and design

3D scanning is fast enough to produce as-built drawings in real-time. A single laser and scanner setup can collect millions of data points per second, letting you update your design models quickly.

These models will also be extremely accurate, ensuring you can complete projects according to your client’s specifications with rich details without extra work or conflicts. You just get fast, precise, and accurate answers to your job site questions, minimizing waste and alterations in the field.

Safety and regulatory compliance

Construction sites are among the most hazardous job sites, but you can make your job sites safer with 3D scanning. The technology lets you assess hard to reach or unsafe locations with ease. It requires no harnesses, complicated machinery, lifts, or cranes. In some cases, your workers can even stay within the safety of their vehicles.

With your crew’s risk exposure minimized, you can easily pass all safety, health, and environmental regulations. 3D laser scanning is non-destructive, produces no pollution, and requires minimal on-site configuration or programming.

Cost-effectiveness and schedule reduction

The extra safety and production gains come with significant cost benefits as well. You can lower your project costs up to seven percent or more just by implementing some form of 3D scanning. The process also takes less than a week to complete, reducing your labor costs as well. These cost benefits often outweigh the initial investment costs for the scanning.

As the technology reduces design errors, you will finish your projects on time and under budget. You can even ensure your clients the accuracy of your design information, minimizing operational shutdowns, delays, and change orders.

Challenges to 3D laser scanning in the construction industry

While adoption grows exponentially, 3D laser scanning is still rare in the construction industry. Most of the adopters tend to be the larger firms with the capital to test unproven technology. Smaller companies still use mostly traditional surveying techniques.

Several integration challenges make switching over to laser scanning a challenge. While there are many attempts to solve these challenges, these drawbacks offer significant risks to any firm willing to implement 3D scanning into their operations.

Expensive upfront investment and operative costs

3D laser scanning will eventually offer high returns for your investment, but you still must cover its high upfront costs to implement it.

Steep learning curve and scope

As with any technology, you must give your workers comprehensive training if you want to reap all the benefits of 3D laser scanning. However, your employees may have a significant skills gap to overcome. Education will help, but it will add to the overall upfront costs.

Beyond the technology itself, your workers must have familiarity with the job site to read and understand the point cloud models it produces. Misunderstandings can lead to failed projects and higher project costs that can undermine the benefits.

An alternative to overcome these problems is subcontracting the services to a specialized company.

Data compatibility

Because 3D laser scanning produces data as computer files, you need software that can read those files to gain any insights from them. Fortunately, most scanning solutions can output the data compatible with:

- Navisworks

- AutoCAD Plant 3D

- Revit

- AutoCAD MEP

- Autodesk Recap

- Bentley MicroStation

- Lecia TrueView

- AutoCAD solids

- Other popular CAD and BIM model formats

Best practices for implementing and using 3D laser scanning in construction projects

3D laser scanning offers numerous benefits to every stakeholder in the life of a construction project, but only if it is done right. However, it can backfire if you do not take the necessary precautions required to ensure success.

If you want to get the most out of the technology while minimizing the downsides, you must implement it the right way. To get you started, we offer the following tips and best practices.

Start 3D laser scanning early

Laser scanning can give you insights throughout the project lifecycle. Therefore, you want to add it to your projects as soon as possible. Starting early will provide you with the best and accurate understanding of the project and job site.

Choose an implementation and stick with it

As with any technology investment, 3D laser scanning is not cheap. You might find it more economical to rent your scanning equipment or to hire a scanning service. You can then formally purchase the equipment once you better understand the returns on your investment.

Use laser scanning in conjunction with other technologies

Laser scanning is just one tool in your tool chest; it is not a silver bullet. Do not forget the other tools at your disposal. There is no shame in using multiple surveying techniques in a single project. Laser scanning can enhance your BIM models along with your CAD ones.

Deciding when and how you will use laser scanning in your projects can help alleviate confusion and spending time and money on unnecessary tasks. You can use the technology to enhance your documentation process, verify existing conditions and progress, or help you coordinate project tasks on site.

Inform your customers about the laser scanning technology you use

Laser scanning has its limitations. Your customers must also understand that scanning requires three different tasks: collecting data, registering the scanned data, and post-processing. You must do all three steps to get the most out of the technology. While you may skip a step or two, your client must understand why and when you must stop production and bring in the scanning equipment.

Generally, you can complete both customer education tasks with a single on-sight demonstration. You can walk your customer through a single scanning cycle and show them the steps you must take to gain insights from the data.

Understand and know the physical space limitations before you scan

Laser scanning can reduce the time required to investigate and survey a job site, but it takes time and has a high upfront cost. The tools also require enough space to function correctly. You can reduce some of the limitations by only using it when and where you need it.

Understand your project's scope

Laser scanning technology is so versatile that you may find other applications that you never considered before. Beyond modeling and surveying a site, you can use the technology to guide workers through a project to ensure everyone is on the same page.

Determine your customer's data delivery requirements

Laser scanned data is only as good as the software you use to read it. Each data processing tool has its requirements and expected data format. If you save your point cloud in the wrong format, you may end up with incomplete or broken models.

Thus, you always want to ask your customers about what data formats they expect. While you are free to change your software as you see fit, you cannot presume your clients can do the same. Some design teams may also find working with the raw scan data more comfortable. Feel free to save the data in multiple formats as needed.

Set project survey controls before scanning

Scanned data models work best when you scan the same area with the same orientation. This protocol lets you see changes and imperfections you may not otherwise see. Therefore, you want to establish a schedule and a set of survey controls before you begin scanning. You can even tie the controls into your overall project control scheme.

Collect more data than you think you need

Establish a dedicated laser scanning team

3D laser scanning technology comes with a steep learning curve. While you could train all of your workers to use it, you will find establishing a scanning team will be more cost-effective.

A dedicated scanning team will have the time and training to fully understand how the technology works and what it cannot do. The group can also work with other project teams, reducing any potential production downtimes. Your company will have the advantage of using the technology for maximum value with minimal costs.

Conclusion

The exponential adoption of 3D laser scanning technology within the construction industry has small firms wondering if they should use the technology as well. While it does offer many benefits, you will only see those benefits if you use the scanning tools properly.

Contact us

Whether you just have a small question or want to get a customized offer from us:

Contact us now.

We are happy to help you.