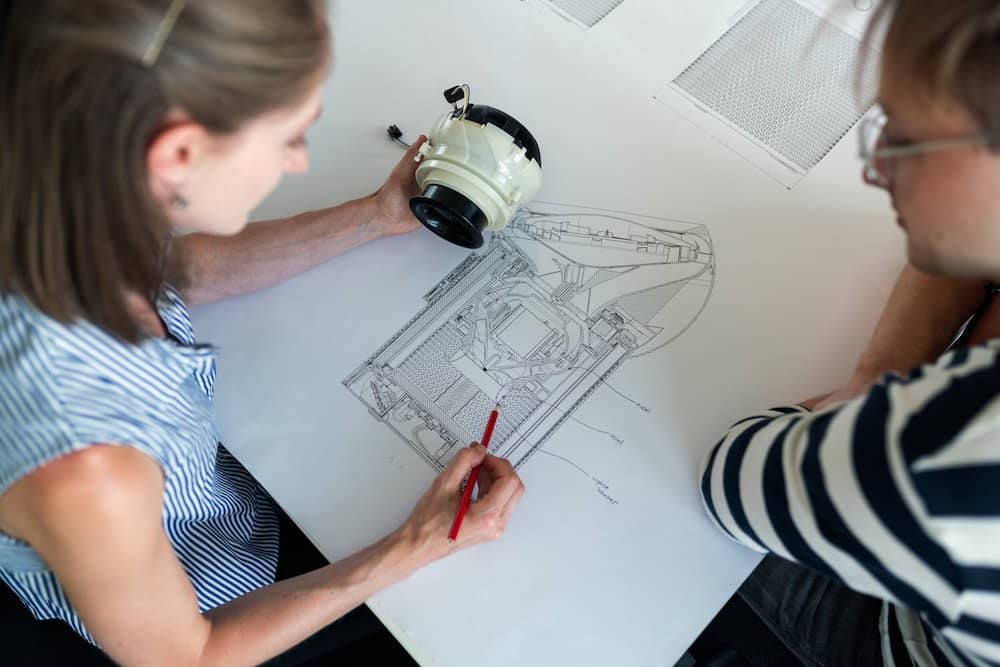

We are happy to advise in all areas, such as:

- Integration of optical measuring equipment in production

- Recording of insurance claims

- Digitization of locomotives

- Retrofit of vessels

- Modernization actions

3D Scanning technology unveils a huge potential

No matter if it is the altitude measurement of a cruise ship, the volume determination of tanks or the analysis and quality assurance of assembly processes.

3D scanning offers a wide range of applications with an enormous potential.

Special projects

altimetry cruise „AIDA“

A complete set of altitude measurements were taken of the cruise ship AIDA. The use of 3D scanners ensured outstanding accuracy and detailed results within a matter of days.

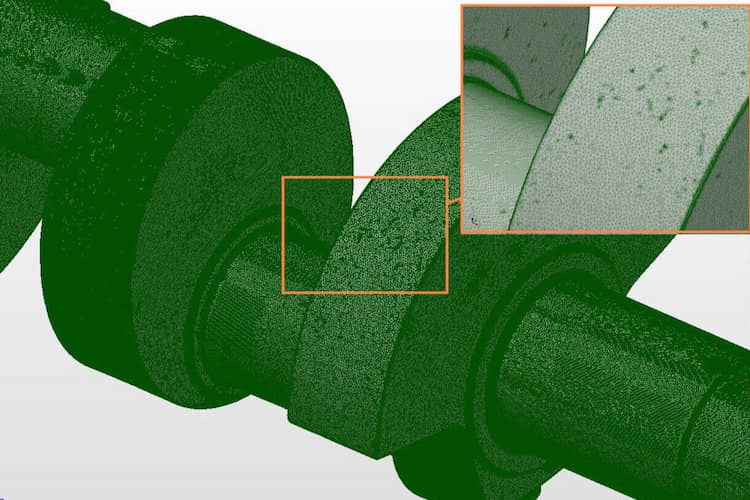

Digitization of a compressor

A gas compressor is a geometrically complex part. Digitizing such a component can provide multiple benefits. Thanks to our extremely accurate articulated arm, with a tactile probing performance from 0.023 mm, we were able to create a digital version to the finest detail.

3D-Modell of a ballast water tank for the correction of trim tables

Ballast water tanks on ships make an essential contribution to floating stability. We were called to help on calculating the filling level and ballast weight.

With our 3D-scanning equipment, we measured the tank from the inside, which extended over 3 floors. Based on this we were able to create a 3D volume model of the tank and simulate different filling levels.

The big advantage of this measurement and simulation is that the tank does not have to be physically aligned for different trim angles or inclination angles.

3D scanning of pipes on ships for manufacturing replacement parts

Many pipes on ships have to be replaced in the course of the product life cycle. Here, too, 3D surveying offers a solution for creating an accurate image of the pipes, which can then be used as a basis for manufacturing new ones.

In this context, we were called to generate 3D models of defective pipes for replacement part production. Especially the position and orientation of the flanges and its holes was of high importance.

The challenges in this project were to capture sufficient surface area of the pipe envelope, as the pipes were located tightly between other pipes at the lowest point in the engine room.

contact us

Whether you just have a small question or want to get a customized offer from us:

Contact us now.

We are happy to help you.