MANUFACTURING

The broad skillset of our manufacturing team allows us to deliver outstanding outcomes with attention to detail and a passion for quality. Find out more about our manufacturing below.

Subtractive manufacturing

Our expertise in mechanical manufacturing spans various materials and industries. With our in-depth specialist knowledge and many years of experience, we are able to meet customer requirements and offer tailor-made solutions.

ADDITIVE MANUFACTURING

For many projects, we build physical demonstrators and prototypes with complex three-dimensional shapes or internal structures. This technology is ideal for producing functional prototypes and high-quality finished models, allowing us to meet tight schedules.

COMPOSITE MATERIALS

Composite materials play a central role in modern manufacturing, particularly in the production of components for air conditioning systems, vehicle interiors, and other applications that require high strength and low weight.

ELECTRICITY

We have a team of electricians and technical experts with extensive experience in electrical installation and software programming. In addition, thanks to our expertise in the design and manufacture of cabin models, we have in-depth knowledge of the CIDS system for aircraft.

fINISHING

In our workshop, we place great emphasis on precision and quality. From the initial idea to the finished product, we work closely with our CMF team (color, material, and finish). This expertise enables us to not only meet aesthetic requirements but also ensure the functionality of our products.

SUBTRACTIVE MANUFACTURING

Our expertise

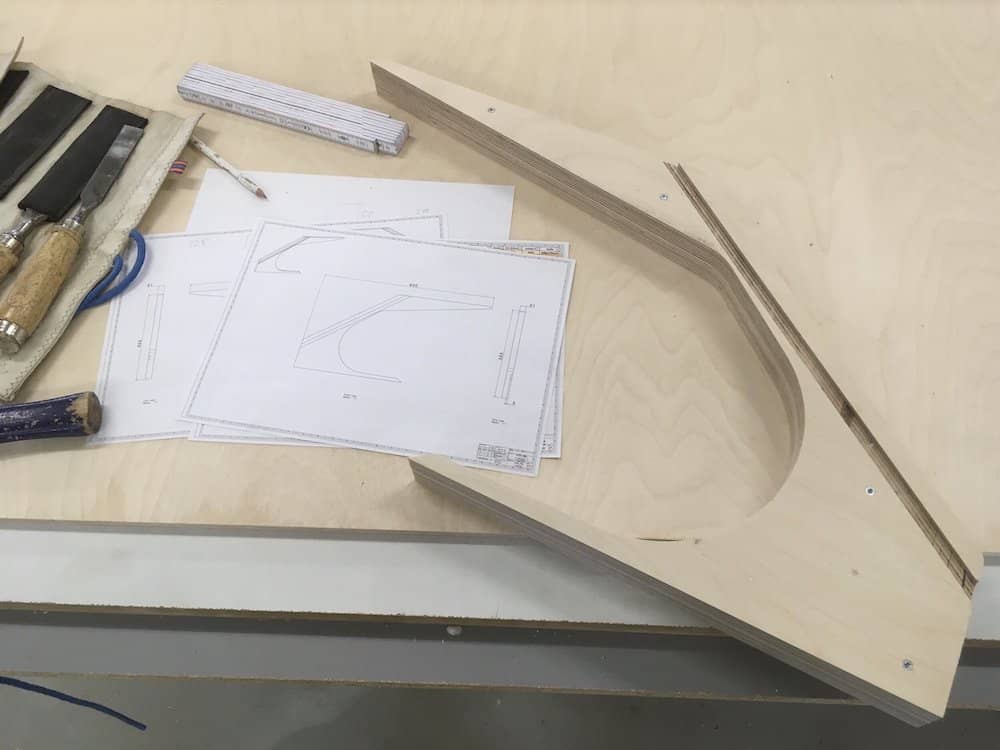

- CNC milling: Production of prototypes from metal, plastic, and wood

- In woodworking, we rely on traditional methods as well as modern CNC technology

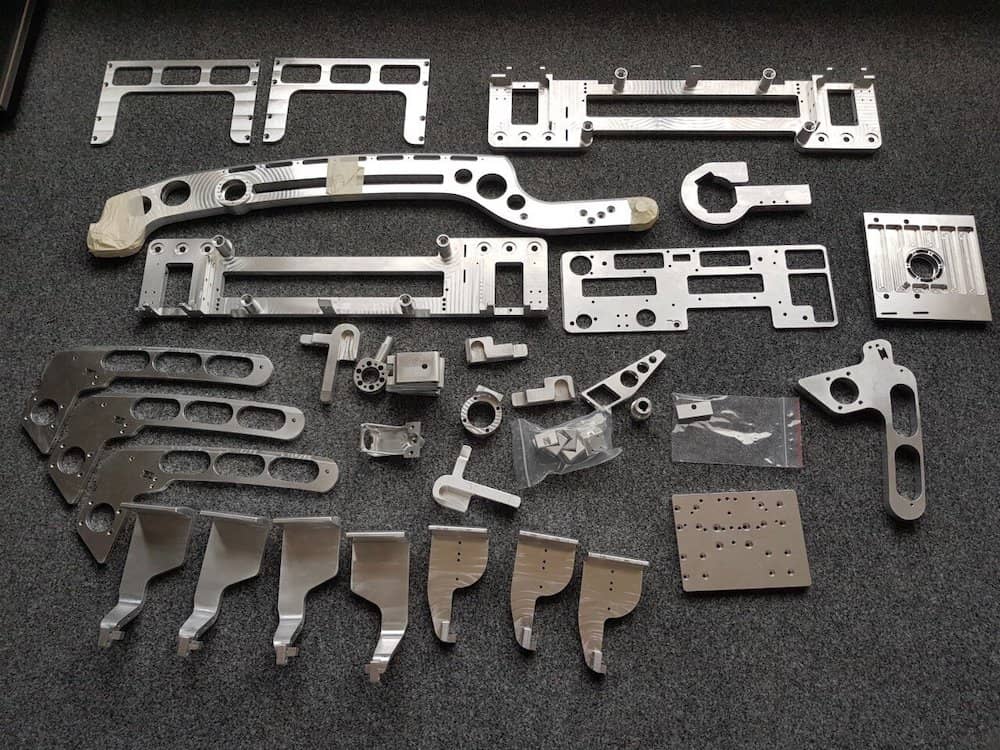

- Laser-cut products: Precision-turned or milled parts

- Cabin demonstrators: Development and manufacture of brackets, frames, and other structural parts.

- FEM simulation: Structural analysis – optimization – efficiency

Activities and production methods

Our extensive range of mechanical processing methods includes:

- Milling: precision and versatility in modern manufacturing.

- Turning: production of cylindrical parts with high accuracy.

- Drilling: drill holes with various diameters and depths.

- Grinding: smoothing and polishing surfaces.

- Laser cutting: production of sheet metal parts, metal housings, and structures.

We use state-of-the-art technologies and machines to manufacture precision parts.

ADDITIVE MANUFACTURING

Our expertise

We have the knowledge and experience to design and optimize parts specifically for additive manufacturing. This includes taking into account design guidelines that are specifically tailored to the respective 3D printing processes and materials. By selecting the appropriate material, we ensure that the manufactured parts have the desired mechanical properties and surface qualities.

For specific applications and requirements, we develop original designs that are specially optimized for additive manufacturing.

Our simulation capabilities enable us to optimize lightweight structures in terms of process parameters.

Our expertise and know-how in this area enable us to develop tailor-made solutions that are precisely tailored to the needs of our customers.

Activities and production methods

- SLM (Selective Laser Melting)

- Aluminum, tool steel, Inconel, stainless steel, titanium, copper

- SLS (Selective Laser Sintering)

- PA12 (with different colors, with aluminum or glass fiber, flame retardant)

- PA 11, PA 6, TPU PEEK HP3

- FDM (Fused Deposition Modeling)

- Others: Multi Jet Fusion, PolyJet, stereolithography…

COMPOSITE MATERIALS

Our expertise

Our team has extensive experience in the design and manufacture of composite parts

- Lightweight construction optimization: We use simulation software to optimize structures for maximum strength and minimum weight

- Sustainable materials: We use environmentally friendly materials and processes to minimize our ecological impact

- High-quality finish

- Simulation capabilities

- Load simulation using FEM analysis

- Weight optimization, optimization of material selection according to application

Thanks to our advanced production methods and in-depth expertise, we are able to supply high-quality composite parts for a wide range of applications.

Activities and production methods

- Part/mold design for composite components (aircraft interiors, yachts, train interiors, automotive parts)

- Design and manufacture of casting molds

- Manufacture of composite laminates in vacuum bags

- Manufacture of sandwich panels (use of various core materials, including environmentally friendly materials such as corn starch)

electricity

Our expertise

- Extensive knowledge of aircraft lighting systems

(X programs) - Development and installation of customer-specific control units/systems

- More than 10 years of experience in creating functional prototypes, including complete electrical installation

- System efficiency: software testing, troubleshooting, software maintenance

- Implementation of VR/AR applications in the mock-up environment to increase information performance

Activities and production methods

- General electrical installations

- Assembly of cable harnesses

- PCB definition and procurement via partner companies

- Software development of embedded systems

- Development of VR/AR applications

- Projection mapping

- CIDS

- Creation of the necessary drawings

Hardware procurement - Hardware installation

- CAM programming (A320, A330, A350)

FINISHING

Our expertise

- Expert knowledge in color, material, and finish (CMF)

- Aesthetics and functionality

- Craftsmanship and innovative design

- Material selection:

- High-quality materials (wood, plastic, metal)

- Sustainable and environmentally friendly options

- Color scheme:

- Selection of matching colors

- Various spraying and painting techniques for consistent results

- Surface finishing

- Sanding and polishing

- Customization

- Custom color mixtures and material combinations

- Tailor-made surfaces for special requirements

Activities and production methods

Our manufacturing techniques include:

- Painting: according to Airbus standards

- Foil wrapping: mock-ups, monuments, trolleys, walls, etc.

- Sewing: curtains, seat covers, etc.

3D printing

The expertise within our team allows us to offer a variety of 3D outcomes such as miniature functional or non-functional prototypes, tools, replacement parts and more, with the optional choice of your required printing material. Due to our familiarity with a wide range of technologies (e.g. stereolithography) we can offer 3D prints with several different properties.

fiber composites

Using fiber composites (GFRP or CFRP) guarantees a superior structural quality which allows high-end surface coating on your requested item. The close cooperation between our manufacturers and our CAD designers assures perfectly implemented and highly professional haptic outcomes.

Hard foams

In cooperation with our partners, we process hard foams in all different densities for CFRP and GRP models in multiple sizes. In order to achieve the perfect outcome for you, we use high-quality machine-based tools for shaping such as saws, drills, lathes and milling machines as well as hand tools for the final touches.

Wood processing

Depending on your specific requirements, we are familiar with both traditional methods as well as modern CNC technology in order to process all different kinds of timber materials. Whether you require a custom-made furniture piece, any kind of shopfitting, model making or the process of veneering – our multi-disciplined manufacturing team can provide it all.

Metal processing

Our expertise and the variety of tools we have access to for metal processing allows us to offer you high-quality laser-cut items as well as precision turned and milled parts. Whether you demand a small or large series or individual parts – we implement your request with your choice of material, such as aluminum, structural steel or stainless steel.

painting room

Our workshop includes a modern and fully-equipped painting room which enables our manufacturers to accomplish work with outstanding accuracy on all surface finishings. Our experts are well-trained on true-to-original varnishes for any kind of requested prototyping for all different industries (e.g. aviation).